http://civilustaad.blogspot.com/

The design of FRP external reinforcement for flexure is quite rational and simple. It is based on Bernoulli’s theory of strain compatibility that plane sections remain plane, which requires ideal bonding between FRP and concrete, and the capability of the concrete to transfer stresses to the FRP laminate by shear. In a beam reinforced inside with steel and externally with FRP, there is typically substantial reserve capacity at steel yielding. After the steel reinforcement yields, the beam can still carry increasing loads, although at a lower rate (with respect to deflections) than prior to steel yielding, and the FRP maintains elastic behavior until failure occurs suddenly. Failure is precipitated by FRP de-bonding, rupturing, or concrete crushing. Every of these modes of failure are brittle, i.e., load capacity is reached with modest inelastic deformation.

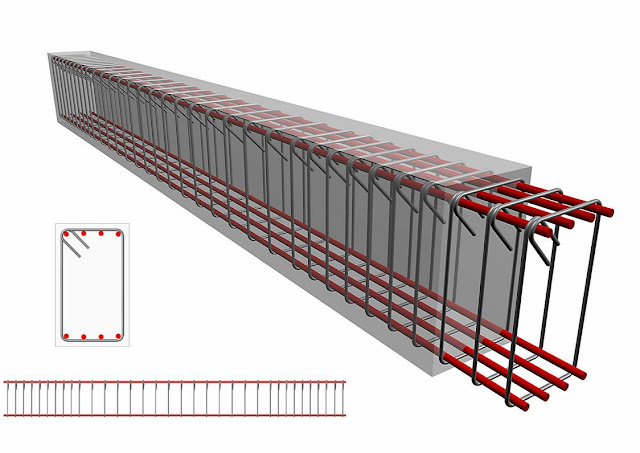

BEAMS

WITH DUCTILITY

Ductility is a enviable structural property since it allows stress redistribution and provides caution of impending failure.

Steel-reinforced concrete beams are under-reinforced by design, so that malfunction is initiated by yielding of the steel reinforcement, followed after substantial deformation at no substantial loss of load carrying capacity, by concrete crushing and ultimate failure. This form of failure is ductile and is guaranteed by designing the tensile reinforcement ratio to be considerably below (ACI 318 requires at least 25 % below) the fair ratio, which is the ratio at which steel yielding and concrete crushing occur concurrently. The reinforcement ratio thus provides a metric for ductility, and the ductility corresponding to the maximum allowable steel reinforcement ratio provides a gauge of the minimum acceptable ductility.

The design of FRP external reinforcement for flexure is quite rational and simple. It is based on Bernoulli’s theory of strain compatibility that plane sections remain plane, which requires ideal bonding between FRP and concrete, and the capability of the concrete to transfer stresses to the FRP laminate by shear. In a beam reinforced inside with steel and externally with FRP, there is typically substantial reserve capacity at steel yielding. After the steel reinforcement yields, the beam can still carry increasing loads, although at a lower rate (with respect to deflections) than prior to steel yielding, and the FRP maintains elastic behavior until failure occurs suddenly. Failure is precipitated by FRP de-bonding, rupturing, or concrete crushing. Every of these modes of failure are brittle, i.e., load capacity is reached with modest inelastic deformation.

No comments:

Post a Comment